The Process

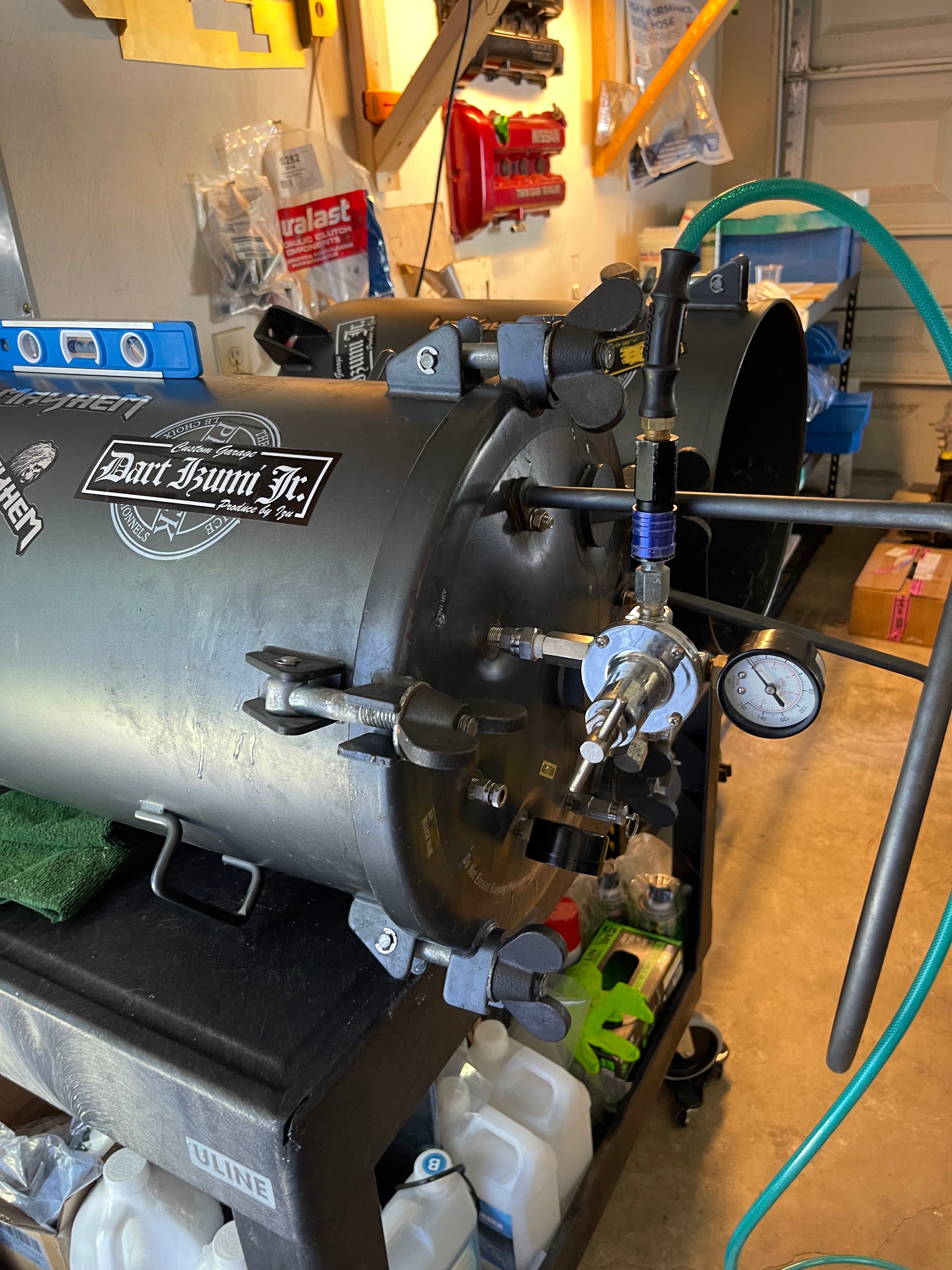

All lenses are replicated via silicone molds. The molds are 2-part molds, and they are modeled/cast using the OEM lenses. When the molds are ready for use, we pour high quality crystal clear epoxy resin into the molds, followed by a 24-hour "cooking" process in our industrial-grade pressure pots. The pots ensure that all air bubbles are squeezed out thanks to the maximum 80 psi (5.44 atmosphere) pressure used which leaves a leveled luxurious clear finish. The pressure process is followed by a 7-hour "baking" process which accelerates the curing process (heat is an accelerant). Each of our lenses is made from crystal clear epoxy that contains UV cut properties. The next process after the lenses are removed from the molds is to "deflash" any leftover resin which amounts to trimming off excess epoxy from the lens itself. This process is then followed by sanding to remove any blemishes that may be present as a result of the casting process. The final step after the sanding is to apply the 2K clear coat for additional UV cut, and to add additional shine to the lenses. The 2K clear coat is good for at least 15 years.

The Process >